Quality products

Automotive

Automotive

- Technical functional components

- Surface components

- Complete assemblies

- Spoiler & diffuser elements

- Fuel filler cap & underride guard

- Instrument panels & centre consoles

- Day-night design

- Interior and exterior components

- and much more

Consume

Consume

- Control panels

- Front elements

- Customised components

- Buttons, knobs, handles, lids,

Decorative mouldings, frames, etc. - Wide range of variants

- Low component weight

- Cost-effective series production

Sanitary

Sanitary

- High-quality lacquered WC lever handle plates,

Shower heads, taps, toilet seats,

Bathtub panelling, shower cubicles

and much more - Good handling and cleaning properties

- Modern, classic or extravagant designs

- Scratch-resistant surfaces

Leisure

Leisure

- Bicycle attachments & fitness equipment

- Toys

- Outdoor equipment

- Skateboards & Scooters

- Cool boxes & containers

- Housing of portable devices

(e.g. lamps, cookers) - and much more

Location

m2 Production area

Employees

Painting plants

Manual painting solutions

Our services for the best quality

System responsibility

System responsibility

Thanks to professional supplier management and good co-operation with carefully selected partners, TECLAC also assumes responsibility for the development and delivery of entire component groups.

quality

Quality management

The name TECLAC stands for quality. Quality assurance is of paramount importance in the company philosophy. Our customers recognise this commitment. For TECLAC, this is a confirmation, but also an obligation and a constant challenge.

Sustainability

Sustainability

We take responsibility for the environment and are committed to a sustainable future. By optimising our processes, we minimise our environmental impact and contribute to the protection of our planet - for a greener and more liveable future!

Employee voices

News

Participation of Hübner-KTB

TECLAC has now taken a forward-looking step: At the turn of the month in April this year, Hübner-KTB Oberflächentechnik GmbH acquired a 45 per cent stake in TECLAC. In...

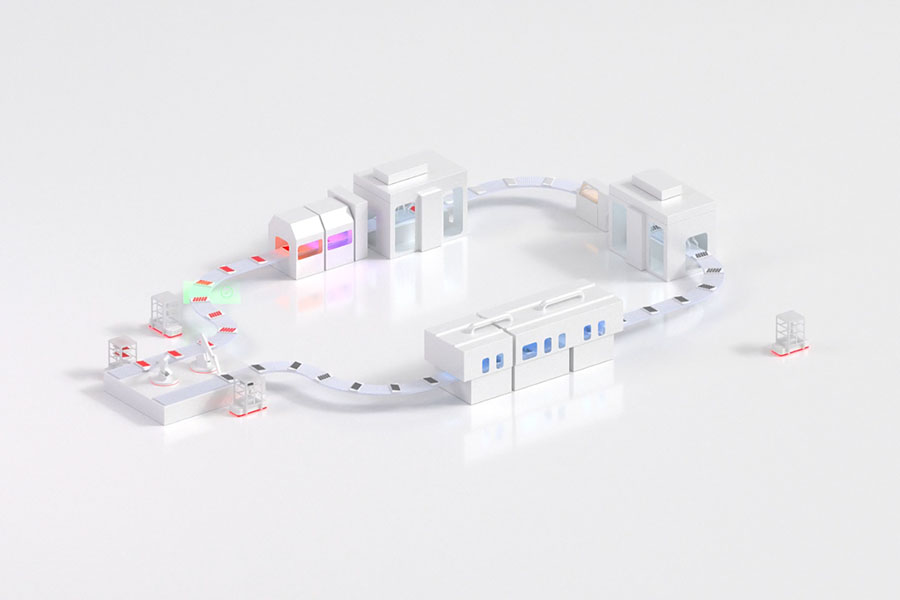

TECLAC invests in comprehensive new painting technology

At the beginning of 2022, a completely redesigned flat belt line went into series production at the Fulda site.

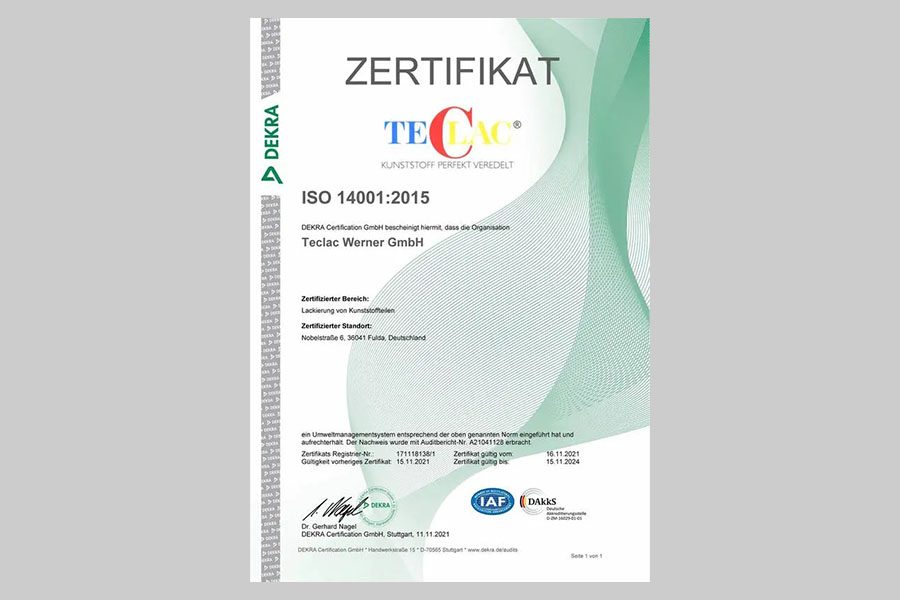

Environmental management system at TECLAC now also certified

Protecting the environment and using resources efficiently is a declared goal of TECLAC's management. An energy management system in accordance with DIN EN ISO 50001...